50 ton Flatbed Trailer

Flatbed trailers are versatile open trailers used to transport a wide range of products and materials. Also known as flat, float, flat deck, and high boy trailers, some of the common products they are used to haul are: flat steel, coiled steel, channel steel, rebar, lumber, pipe, pre-cast concrete, building materials and container etc.

Product Name: 50 ton Flatbed Trailer

Price:Direct factory. Order now and get 10% off.

Different Parameters, Different Price

Contact us for more infos. Whatsapp/Phone Number: +86 18615520624

Email: sales@vehiclemaster.com

50 ton flatbed trailer is a semi-trailer with container structure. flatbed trailer Mainly used in ships, ports, routes, highways, transfer stations, bridges, tunnels. The logistics system of road and multimodal transport.

(1)It is specially used for the transportation of various containers. It can be used repeatedly for a long time with sufficient strength.

(2) The goods can be directly loaded in the consignor's warehouse and unloaded in the consignee's warehouse by using the container for transshipment. When the vehicle or ship is replaced midway, it is not necessary to take the goods out of the box for replacement.

(3) It can carry out fast loading and unloading, and commercial flatbed trailer can be directly and easily reloaded from one means of transport to another.

(4) It is convenient for loading and unloading goods to meet the personalized needs of customers. According to the customer needs tooling guarantee, stable quality, reliable performance.

Configuration Sheet: 50 Ton Flatbed Trailer

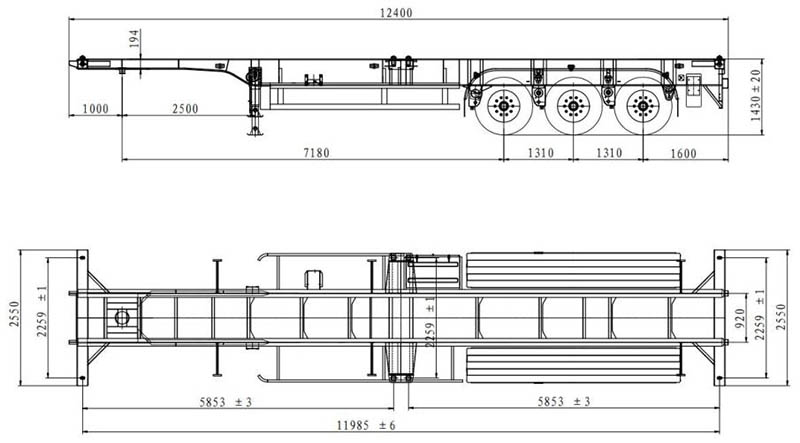

Overall Specifications:

Payload Capacity: 50 tons (100,000 lbs or 45,359 kg)

Length: Varies based on the specific model, typically between 48 and 53 feet (14.6 - 16.2 meters)

Width: Standard width of 8.5 feet (2.6 meters)

Deck Height: Around 48 inches (1.2 meters)

Axles: Typically equipped with 3 or more axles

Suspension: Heavy-duty air suspension system

Deck Specifications:

Type: Flatbed (open) trailer with a flat and level platform for carrying freight

Deck Material: High-strength steel or aluminum

Deck Length: Varies, commonly between 40 and 50 feet (12.2 - 15.2 meters)

Deck Width: Standard width of 8.5 feet (2.6 meters)

Decking Surface: Non-slip surface for safety and stability

Stake Pockets: Multiple stake pockets along the sides of the deck for securing cargo

D-Rings: Integrated D-ring tie-down points on the deck for additional cargo securing options

Loading and Unloading Features:

Rear Loading: Equipped with a rear loading ramp for easily loading and unloading heavy equipment or vehicles

Loading Height: Compatible with loading docks and loading bays of standard heights

Forklift Accessible: Smooth deck surface and sufficient ground clearance to accommodate forklifts

Braking and Lighting:

Braking System: Equipped with air brake system or electric brake system, depending on the trailer type

Lights and Reflectors: Full LED lighting system with rear lights, brake lights, turn signals, and reflectors for optimum visibility and safety

Wiring: Adequate wiring and connectors for seamless functionality of all lights and signals

Additional Features:

Toolboxes: Optional toolboxes mounted on the trailer frame for storage of straps, chains, and other equipment

Headboard: Optional headboard (or bulkhead) to protect the tractor's rear window from cargo during transportation

Tarping System: Optional tarping system for protecting the cargo from weather elements

Load Capacity Indicators: Optional load capacity indicators or weighing systems for ensuring compliance with weight limits and regulations.

Note: The specifications provided above are general and may vary depending on the specific manufacturer and model of the 50 ton flatbed trailer. Reference our specification sheet for precise details.

Contact us for more infos. Whatsapp/Phone Number: +86 18615520624

Email: sales@vehiclemaster.com

Features of flatbed semi-trailer

1. Steel structure: The steel frame is made of top hot-rolled or rolled steel plates, and the longitudinal beams are automatically welded, and the advanced sanding and painting process is used as the preliminary treatment.

2. Different types of suspensions are designed for various operating conditions: bogie suspension; air suspension; mechanical suspension.

3. Lamp assembly adopts advanced LED lamp, high-quality PC, casting wiring harness with dual circuit design.

4. Optional automatic tire inflation and pressure sensor system to improve safety and fuel economy.

5. State-of-the-art testing equipment: analyze the composition, hardness, and phase of the metal to ensure the standard of the processed material; check and modify weld defects, paint thickness, and adhesion to ensure the quality of the finished product.

Our factory

We are direct manufacturer and we have strong producing capacity and R&D capacity!Our raw material and OEM parts including axle, suspension, tire, are purchased centralizedly by famous brand , every node will be inspected strictly. Moreover, advanced equipment rather than only worker is been applied during the whole producing process to ensure the welding quality.

Related News

Submitted successfully

We will contact you as soon as possible